PyroPhobic Systems, a provider of fire-resistant thermoplastic resins for batteries, has announced that its LithiumPrevent 200 material has been selected for application in GM’s Ultium battery platform. After two years of collaboration between PyroPhobic Systems and GM’s engineering personnel, the material has been certified for safety and compliance, and will replace traditional glass-filled plastic battery components.

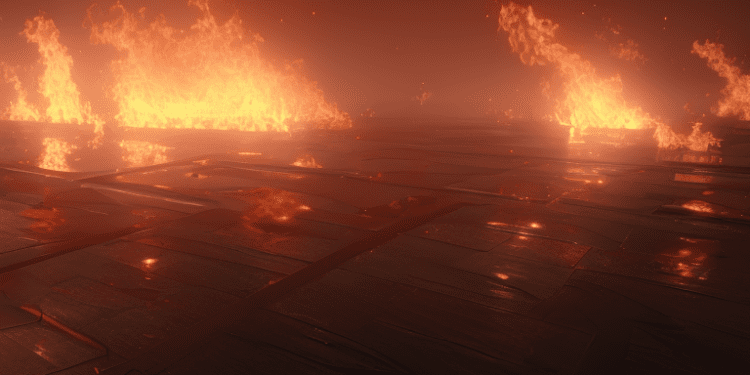

The LithiumPrevent 200 material has “unique intumescent properties, meaning it expands to create a barrier, reducing the propagation of fire,” according to PyroPhobic. This will ensure a safer drive for motorists by mitigating thermal runaway events. PyroPhobic Systems combined forces with Moulded Precision Components (MPC) to bring superior part design considerations and leading-edge injection molding capabilities that are needed for this demanding project.

John Page, President and CEO of PyroPhobic Systems, said: “We are proud to have been selected by GM for this important project. Our products are listed with certified testing laboratories such as Underwriter Laboratories and Intertek Testing Services, so customers can be sure of their safety and compliance.”

The selection of LithiumPrevent 200 is a major milestone for PyroPhobic Systems, and demonstrates the company’s commitment to providing safe and reliable fire-resistant thermoplastic resins for batteries.

FAQ

Q1: Are electric car batteries recyclable?

A1: Yes, electric car batteries are recyclable.

Q2: Are electric car chargers free?

A2: It depends on the charger and the location. Some electric car chargers are free, while others may require a fee.

Q3: Can electric car batteries be rebuilt?

A3: Yes, electric car batteries can be rebuilt with the right tools and knowledge.