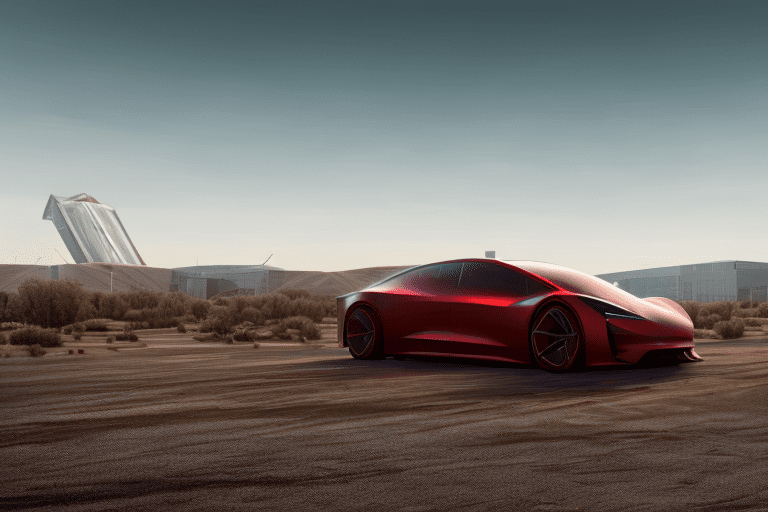

Tesla is continuing to expand its production capabilities with the delivery of a 9 ton (8.2 metric tonne) press to its Giga Factory in Austin, Texas. This is the second press to be delivered to the factory, with the first arriving in January. The two presses are larger than those at Tesla’s factories in Berlin and Shanghai, and are speculated to be used in the production of the company’s Cybertruck.

The press was shipped from IDRA Group’s Italian factory and arrived at the port of Houston. It is the largest of its kind in the world and will enable Tesla to produce single-body castings for the Cybertruck. To make this possible, Tesla’s materials engineers had to develop a new aluminium alloy that could flow into all the intricate areas of the die before setting.

Tesla has said it will begin production of the Cybertruck this year, but high volume production is not expected until 2024. The delivery of the press is a major step forward for Tesla in its efforts to bring the Cybertruck to market. It also demonstrates the company’s commitment to innovation and its ability to develop new technologies to meet its production needs.

Daniel Bleakley is a clean technology researcher and advocate with a background in engineering and business. He has a strong interest in electric vehicles, renewable energy, manufacturing and public policy. With the delivery of this press, Tesla is taking a major step forward in its mission to revolutionize the automotive industry.

FAQ

Q1: Are electric car batteries recyclable?

A1: Yes, electric car batteries are recyclable.

Q2: Are electric car chargers free?

A2: It depends on the charger and the location. Some electric car chargers are free, while others may require a fee.

Q3: Can electric car batteries be rebuilt?

A3: Yes, electric car batteries can be rebuilt with the right tools and knowledge.