Here’s a story we hear often: a CPO or fleet operator wants to deploy a large-scale EV charging facility, but the project is delayed for months or years because the local utility is waiting for the necessary transformers to be delivered. (Two out of two subjects of infrastructure articles in our current print issue—XCharge’s Alex Urist and EnviroSpark’s Aaron Luque—mentioned this bottleneck.)

Transformers are ubiquitous and essential pieces of low-tech equipment but, as TechCrunch’s Tim De Chant notes, they’ve changed little since they were first developed in the late 1800s. The advent of EVs, distributed renewable energy and battery storage has not only created demand for transformers that has far outstripped supply, it has also highlighted the need for smarter transformers with features such as bidirectionality and voltage/frequency regulation.

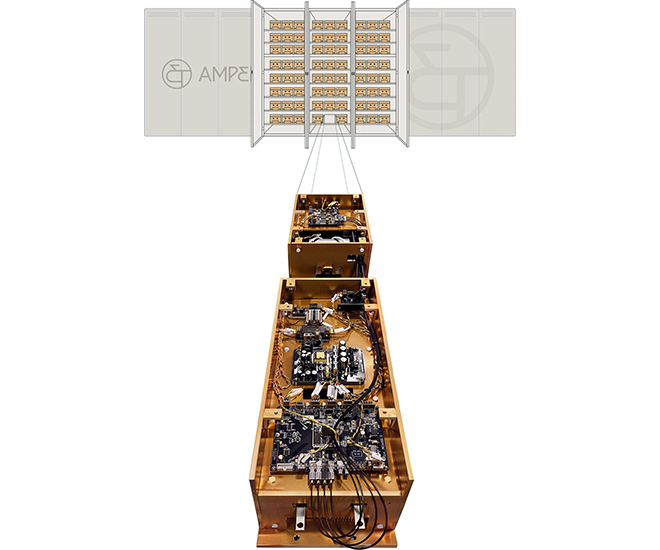

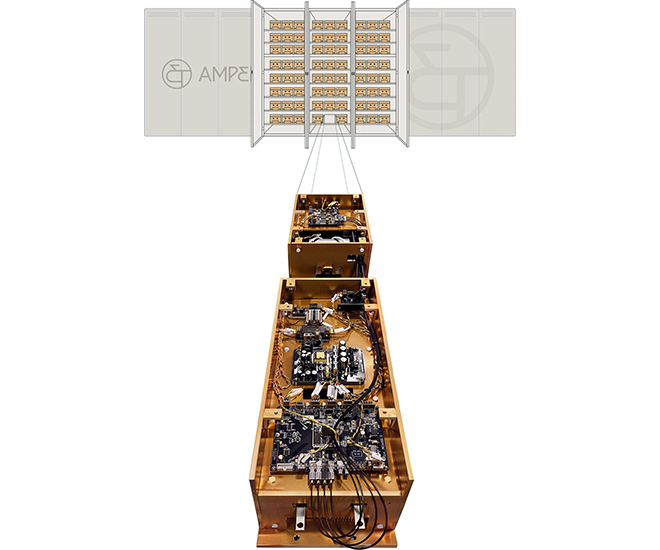

Power electronics startup Amperesand has developed silicon-carbide solid-state transformer technology that it says can make transformers more capable and more compact. The company recently raised $12 million in a seed funding round, which it will use to commercialize its technology.

Amperesand co-founder and VP of Engineering Anshuman Tripathi told TechCrunch that today’s passive transformers don’t offer the uniformity that modern gadgets like solar arrays, whole-house batteries and EV fast chargers require. A solid-state transformer features “an active front end” that can smooth out voltage and power levels, helping renewable generators and EVSE function more efficiently.

Electric utilities are famously conservative, and Amperesand doesn’t expect them to get on board for several years, so it’s starting out by marketing its solid-state transformers to EV charging firms.

“EV charging is a great use case,” said Phil Inagaki, Amperesand’s interim CEO. “The scale of what people are contemplating to deploy in the world with EV charging creates the largest market for transformers.”

Another big selling point for the EVSE market: solid-state transformers are smaller than the traditional kind, and have lower cooling requirements. Inagaki said his company’s units require up to 75% less space. They’re also modular, so they can be easily scaled to fit different sites. “If you want a fast charging station in a city, you may not have a lot of room. People in the fast-charging space, I’ve been surprised, they bring it up more than I thought.”

Amperesand doesn’t plan to build much manufacturing infrastructure apart from some final assembly sites. It will rely on semiconductor manufacturers to make the silicon-carbide devices, and other suppliers to provide printed circuit boards. The company plans to deliver its first units to the US and Singapore in 2025, and to start volume production the following year.

“Old transformers are based on iron cores and oil coolants. These things are very hard to scale in manufacturing,” Inagaki said. “Nothing advances in performance and cost like semiconductor tech.”

Source: TechCrunch