South Korean automotive supplier Hyundai Mobis has developed a new battery cell cooling material to prevent EV battery overheating during ultra-fast charging.

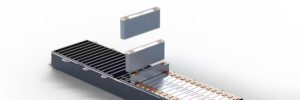

This material, referred to as the Pulsating Heat Pipe, comprises aluminum alloy and refrigerant and is placed between battery cells to limit internal battery temperature spikes during rapid charging. Even when battery heat generation increases during ultra-fast charging, the material is expected to reduce EV charging time by implementing a stable thermal management system that can withstand the heat.

Pulsating heat pipes are metal-tube-shaped thermal conductors used for cooling electronic devices such as computer CPUs and smartphones, diffusing heat through the vibration and circulation of refrigerant internally. They rapidly move the heat from overheated battery cells to the exterior.

Battery systems are typically constructed by adding battery management systems (BMS), cooling fans and various electronic devices to multiple battery modules. Placing PHPs between each battery cell quickly transfers the heat generated in each cell to cooling blocks, stably controlling the internal temperature at the module level.

Hyundai Mobis has developed a press process that enables large-scale continuous production in the manufacturing stage, simplifying the PHP production process and reducing costs. To facilitate mounting on vehicle batteries, it has developed PHPs with a thickness of 0.8 mm, which is thinner and has a larger area than standard heat pipes, which are approximately 6 mm.

Source: Hyundai Mobis

South Korean automotive supplier Hyundai Mobis has developed a new battery cell cooling material to prevent EV battery overheating during ultra-fast charging.

This material, referred to as the Pulsating Heat Pipe, comprises aluminum alloy and refrigerant and is placed between battery cells to limit internal battery temperature spikes during rapid charging. Even when battery heat generation increases during ultra-fast charging, the material is expected to reduce EV charging time by implementing a stable thermal management system that can withstand the heat.

Pulsating heat pipes are metal-tube-shaped thermal conductors used for cooling electronic devices such as computer CPUs and smartphones, diffusing heat through the vibration and circulation of refrigerant internally. They rapidly move the heat from overheated battery cells to the exterior.

Battery systems are typically constructed by adding battery management systems (BMS), cooling fans and various electronic devices to multiple battery modules. Placing PHPs between each battery cell quickly transfers the heat generated in each cell to cooling blocks, stably controlling the internal temperature at the module level.

Hyundai Mobis has developed a press process that enables large-scale continuous production in the manufacturing stage, simplifying the PHP production process and reducing costs. To facilitate mounting on vehicle batteries, it has developed PHPs with a thickness of 0.8 mm, which is thinner and has a larger area than standard heat pipes, which are approximately 6 mm.

Source: Hyundai Mobis