A key challenge in developing Battery Electric Vehicles (BEVs) is extending the driving range through improved energy efficiency. Unlike fossil fuels, batteries have a lower energy density, necessitating large-capacity batteries to match the range of internal combustion engines, which inadvertently increases vehicle weight and decreases energy efficiency. Thus, there is a pressing need for BEVs to achieve longer ranges with fewer batteries.

Enhancing driving range with fewer batteries hinges on improving energy efficiency via high-efficiency and miniaturized powertrains. High efficiency reduces powertrain losses, while miniaturization cuts vehicle weight and driving losses. Therefore, high efficiency and miniaturization of motor drive systems are vital in automobile electrification. This requires accurate measurement of the input/output power of inverters and motor power to grasp efficiency and losses.

Adopting wide-bandgap semiconductors like SiC (Silicon Carbide) and GaN (Gallium Nitride) has recently elevated inverter switching frequencies, cutting losses and presenting new opportunities for inverter design and performance evaluation. However, this progress introduces new measurement challenges, creating a demand for wideband and high-precision power measurements that traditional methods cannot fulfill. Explore how we tackle these emerging challenges and revolutionize BEV development.

The Challenge

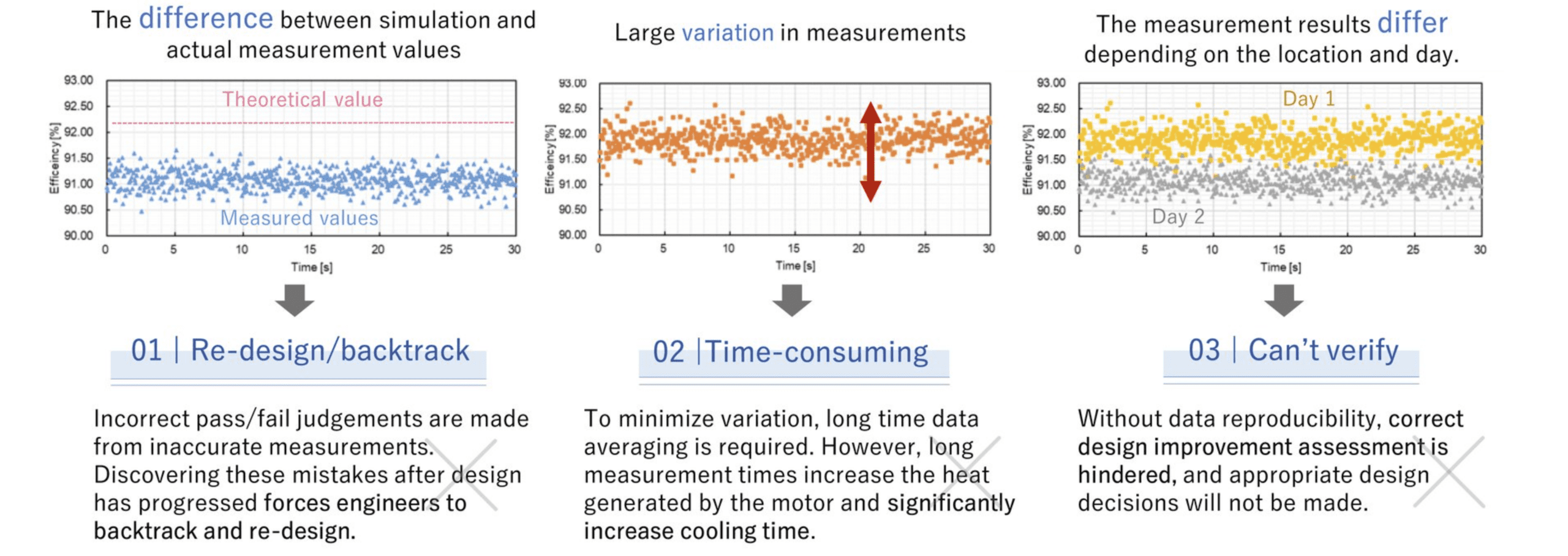

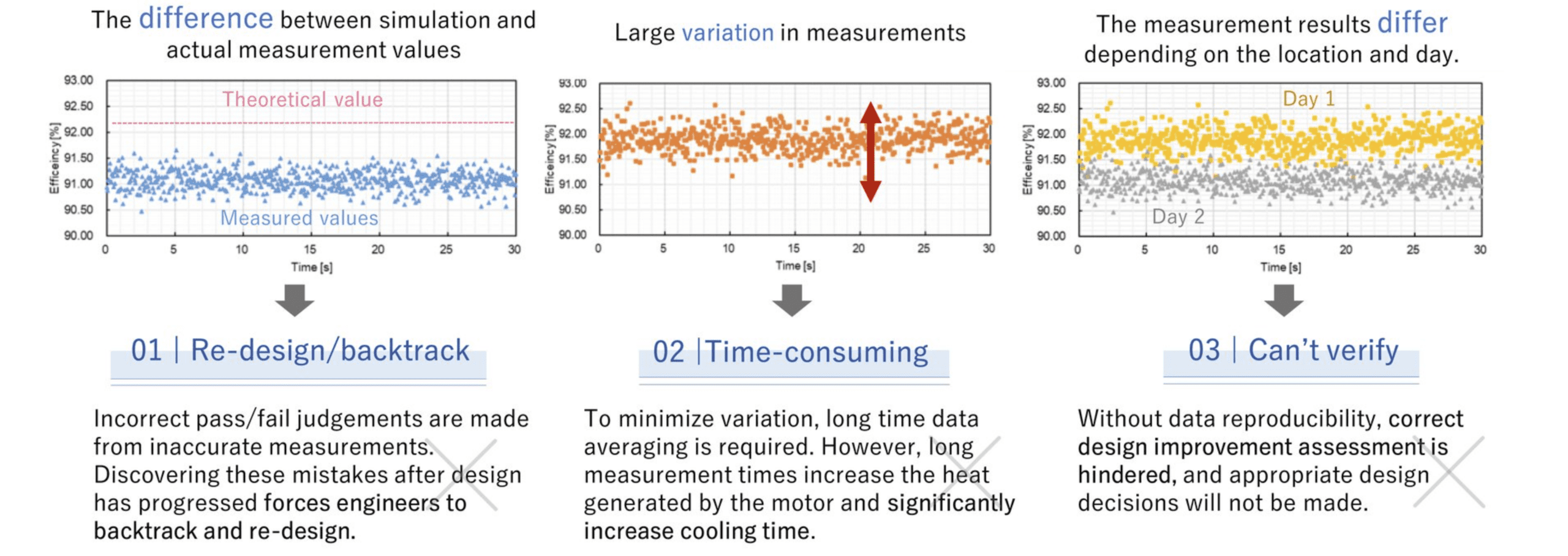

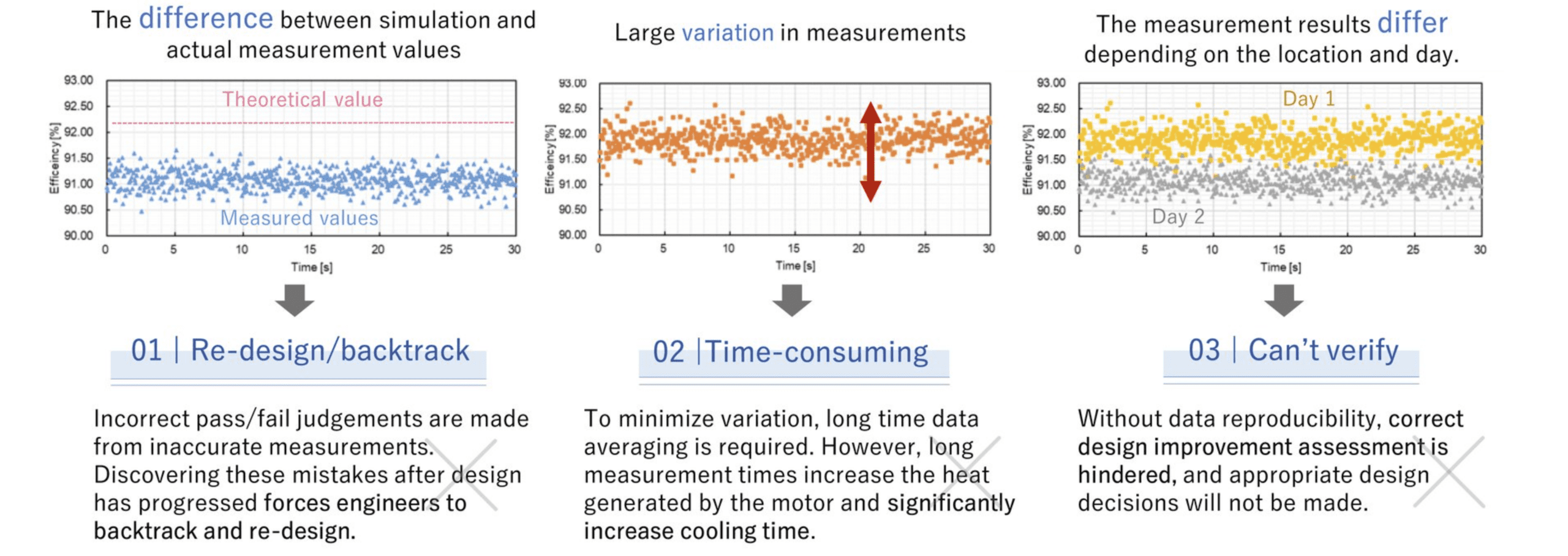

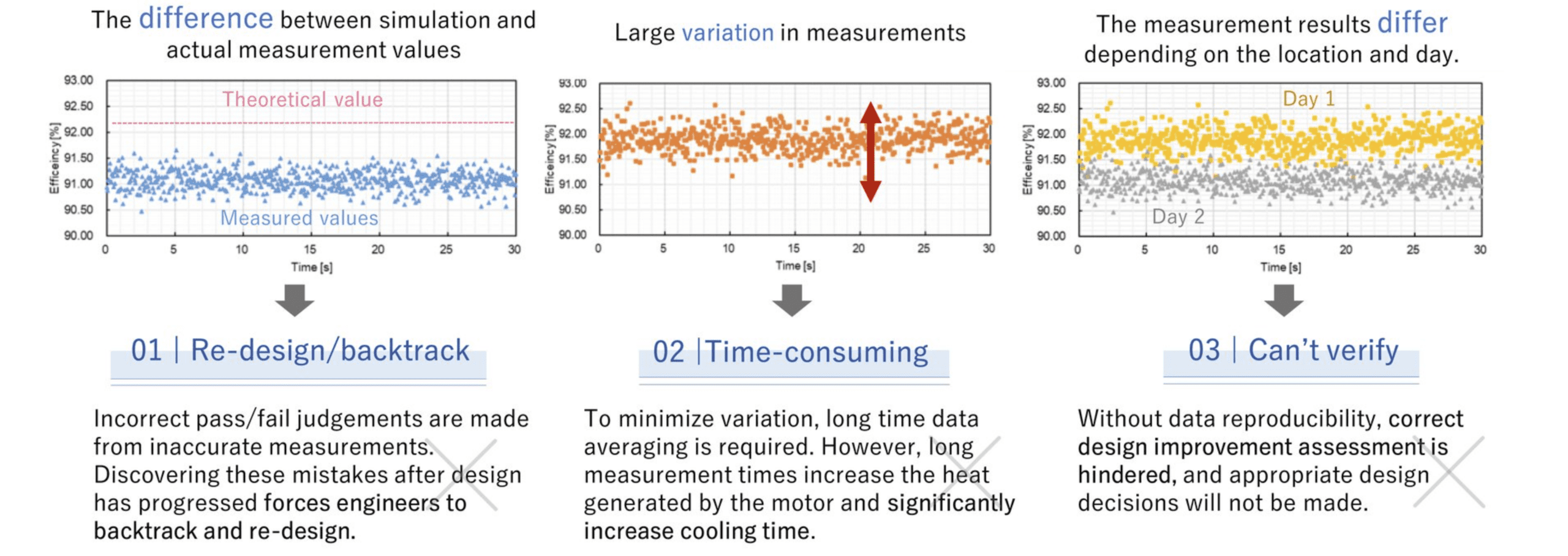

EV engineers on the front line of improving inverter and motor efficiency frequently face several significant challenges:

- Discrepancies between simulations and actual measurements: Theoretical models and real-world operation can differ, complicating design optimization.

- Measurement variability: Inconsistent data under identical conditions and differing results based on environmental factors can hinder reliability.

- High-frequency measurement errors: Conventional methods struggle with errors due to high-frequency switching frequencies in inverters, making it difficult to obtain precise readings.

These challenges are largely due to measurement errors in high-frequency components introduced by the switching frequency of inverters. Inverter voltage and current waveforms can be segmented into two primary frequency bands: the fundamental wave and its harmonic components at 1 kHz or lower and the switching frequency and its harmonic components ranging from several tens of kHz to several hundreds of kHz. While general power analyzers can accurately measure the lower frequency band, they struggle with the higher frequency band, leading to significant measurement errors. As a result, accurately measuring high-frequency power is crucial in inverter development, and suitable measuring instruments capable of handling such measurements are essential.

Meeting Modern Inverter Needs

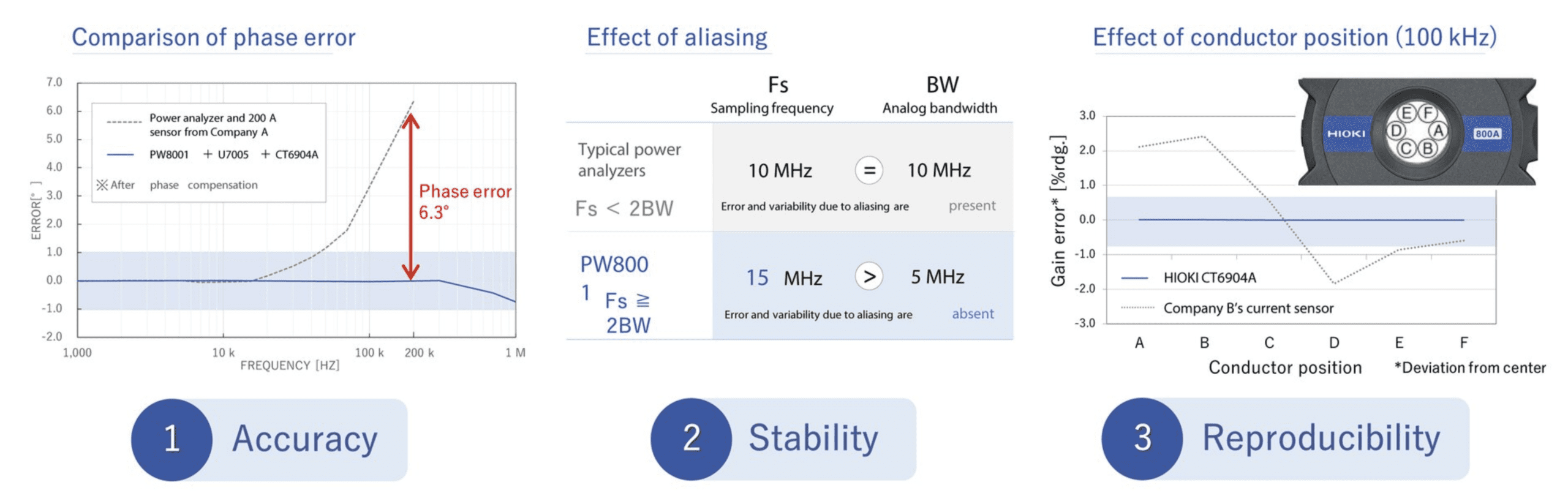

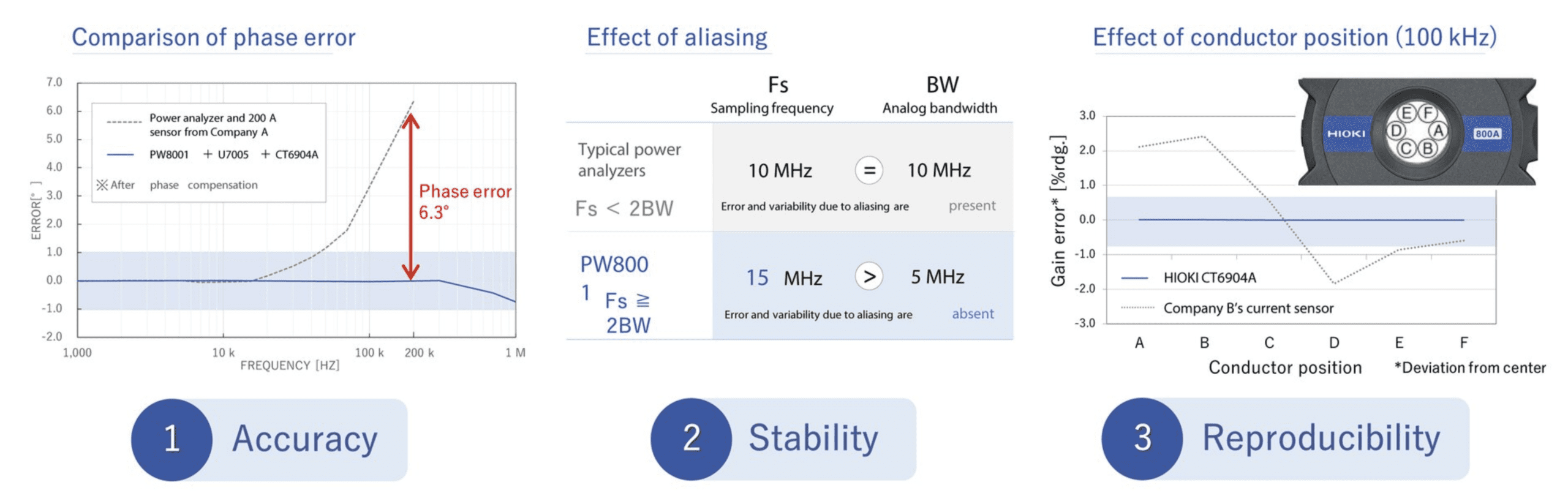

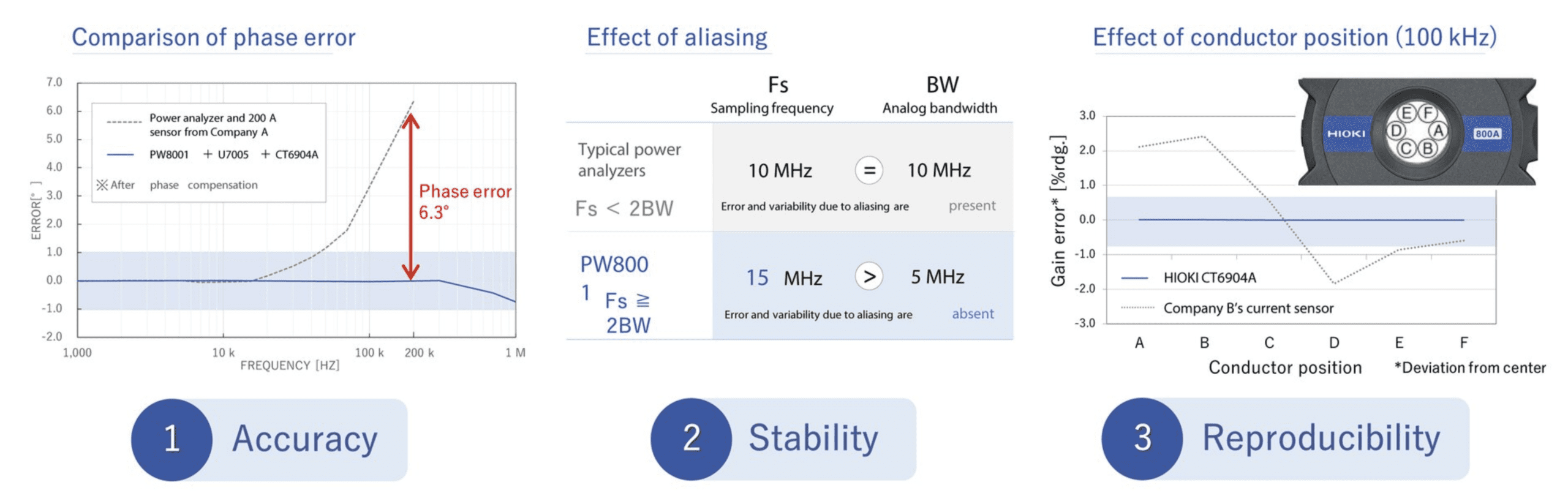

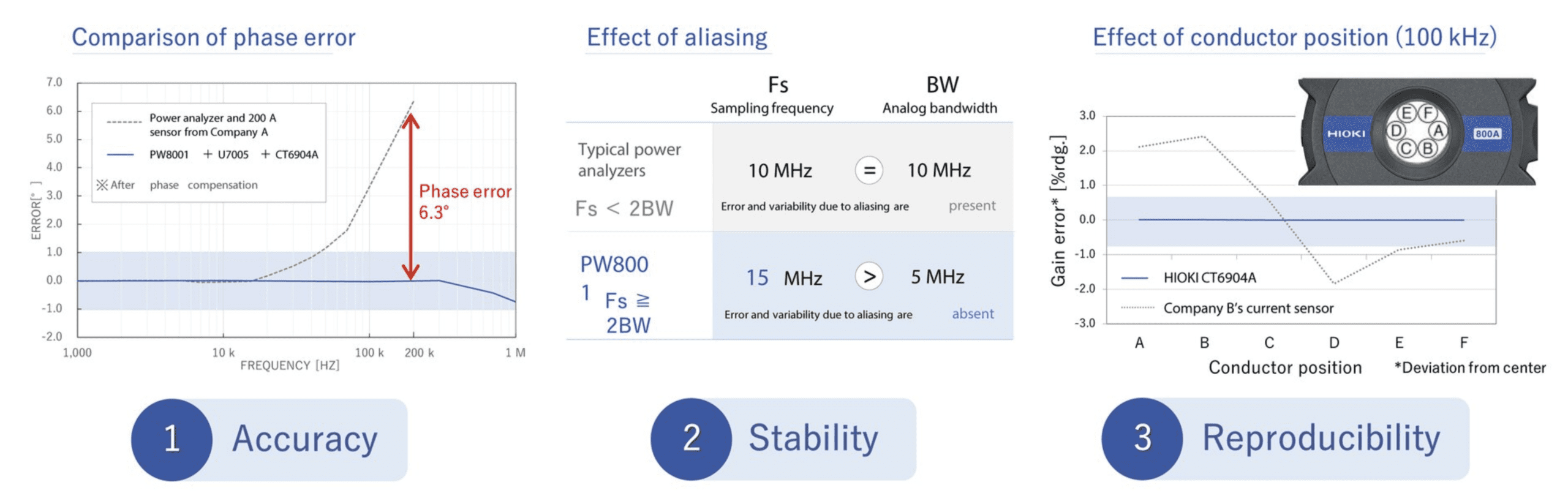

1. Accuracy

One of the most significant contributors to measurement errors in high-frequency power is phase error. Traditional power analyzers paired with standard current sensors often introduce substantial phase errors at high frequencies, hampering the precision of measurements for switching frequencies and their harmonic components. However, Hioki has the advantage of developing its current sensors, allowing for a comprehensive understanding of their unique characteristics. This deep knowledge enables exceptional phase correction, ensuring accurate measurements even in high-frequency domains. This prowess significantly elevates the accuracy of evaluating the high-frequency characteristics of inverter and motor drive systems, bolstering the reliability of development and performance assessments.

2. Stability

A key contributor to measurement instability is aliasing. General power analyzers, with a sampling frequency of 10 MHz and a frequency band of 10 MHz, fall short of the required sampling frequency—at least double the frequency band for precise measurements—leading to aliasing errors. Conversely, HIOKI’s PW8001 boasts an impressive 15 MHz sampling frequency, supporting wideband measurement of 5 MHz and effectively preventing aliasing. This ensures consistent and reliable results, even during extended measurement periods.

3. Reproducibility

General current sensors may exhibit fluctuating measurement values in high-frequency ranges due to the influence of conductor position. If measurement values differ each time, it may be due to misalignment of the conductor position. HIOKI’s current sensors employ a unique coil and shield structure, enabling measurements that are not affected by conductor position even in high-frequency ranges. This innovation allows for reproducible and accurate measurements.

Elevate Your EV Projects

Hioki’s PW8001 sets itself apart from traditional testers by providing accurate, stable, and reproducible high-frequency power measurements. For EV engineers and enthusiasts dedicated to advancing EV technology, the PW8001 is an indispensable tool that ensures precision and reliability in powertrain development.

Explore our solutions to learn more about future-proofing your powertrain test facilities and embrace the electrifying future of mobility.