Ford has announced a massive $1.3 billion (1.8 billion Canadian dollars) investment into the Oakville Assembly Complex in Ontario to transform it into a Canadian hub of electric vehicle manufacturing. The plant will be renamed the Oakville Electric Vehicle Complex and will repurpose existing buildings into a state-of-the-art facility that will leverage Oakville’s experienced workforce. The retooling and transformation of the site into a high-volume manufacturing hub for North American EVs will begin in the second quarter of 2024, with production of next-generation electric vehicles to start in 2025.

Ford has not yet revealed which EV models it plans to make in Oakville, but the factory’s 3,000 workers currently build the Ford Edge and Lincoln Nautilus mid-size SUVs. Ford claims to be the full-line automaker committed to producing passenger EVs in Canada for the North American market, though Stellantis also confirmed last year that it will produce passenger EVs based on the STLA Large platform in Windsor, Ontario.

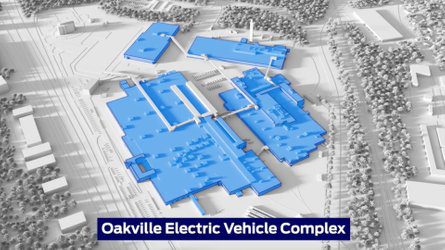

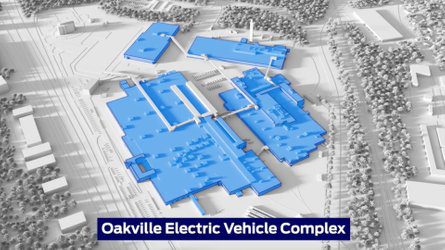

The current 487-acre Oakville site includes three body shops, one paint building, and one assembly building. Ford will retool these buildings and consolidate the three body shops into one, as well as add a new 407,000 square-foot on-site battery plant to the transformed campus. The battery site will utilize cells and arrays from BlueOval SK Battery Park in Kentucky, and workers at Oakville will take these components and assemble battery packs that will then be installed in vehicles assembled on-site.

Ford is taking a diverse strategic approach to transforming its industrial system to expand EV production by building new greenfield sites – such as BlueOval City in Tennessee – and transforming existing manufacturing sites like in Oakville and Cologne, Germany. In addition, Ford is also modernizing its vehicle assembly campus in Cologne, Germany, transforming it into the Ford Cologne Electrification Center, which will build the electric Explorer SUV for Europe. Finally, Ford, LG Energy Solution and Koç Holding have signed an MoU to build one of the largest commercial electric vehicle battery cell production facilities in the European region near Ankara, Turkey. All in all, Ford will invest $50 billion globally in electric vehicles through 2026.

Jim Farley, Ford president and CEO, said: “Canada and the Oakville complex will play a vital role in our Ford+ transformation. It will be a modern, super-efficient, vertically integrated site for battery and vehicle assembly. I’m most excited for the world to see the incredible next-generation electric and fully digitally connected vehicles produced in Oakville.”

Ford’s announcement regarding Oakville is the latest in a line of massive manufacturing investments in North America. These investments are part of Ford’s commitment to producing passenger EVs in Canada for the North American market, as well as expanding EV production globally through new greenfield sites and transforming existing manufacturing sites.

FAQ

Q1: Are electric car batteries recyclable?

A1: Yes, electric car batteries are recyclable.

Q2: Are electric car chargers free?

A2: It depends on the charger and the location. Some electric car chargers are free, while others may require a fee.

Q3: Can electric car batteries be rebuilt?

A3: Yes, electric car batteries can be rebuilt with the right tools and knowledge.