GROB is a pioneer of electromobility: The manufacturing technology and process expertise of the Bavarian family-owned company are used by more than two-thirds of all suppliers of EVs. GROB has earned this market leadership not only through courage and foresight, but also through high quality standards. With its comprehensive portfolio of quality solutions, ZEISS helps to always achieve these standards and noticeably increase productivity.

Electrification is a key economic and ecological success factor – especially in the mobility sector. It is often said that Germany has been left behind internationally when it comes to electromobility. But at GROB, a supplier of manufacturing and automation systems, they only smile at such statements. Martin Negele is head of quality assurance at the long-established Mindelheim-based company. He says: “At GROB, we recognized several years ago that the future belongs to e-drives.”

“At that time, this was still a controversial topic, but we took the plunge.” This has paid off: “Today, we have a 67 percent market share in stator technology alone. If you look at an e-drive train, it is very likely that our production technology is behind it,” Martin Negele explains. GROB earns this leading role mainly by striving for uncompromising quality. To ensure this, the company relies on a close partnership with ZEISS.

With its Industrial Quality Solutions division, ZEISS is the only provider to offer a complete portfolio of state-of-the-art quality solutions: “We combine microscopic, tactile and optical measurement technology to achieve optimum results”, says Martin Negele. This means that even the production of a demanding part such as a stator can be fully covered – with maximum certainty and productivity.

Stator: Challenges in manufacturing and quality assurance

In addition to many other advantages, the drive technology of EVs impresses with its fundamentally simple design: In an electric motor, a rotating electromagnet, the rotor, turns in the magnetic field of an immovable permanent magnet, the stator. However, the production of these components, especially the stator, is anything but simple – even if, roughly speaking, it only consists of a sheet metal housing, the laminated core, and induction coils made of coated copper. Even with such a “simple” component, however, there are high performance requirements today. For this reason, automotive manufacturers are also increasingly using hairpin technology, i.e. plug-in coils, instead of winding wire coils for their stators.

Hairpin coils have major advantages, including higher motor performance combined with lower weight. And hairpins can be mass-produced more easily and efficiently – an important aspect in view of the rising demand for EVs.

“As advantageous as hairpins are as a finished product, their manufacture is demanding, especially when it comes to bending and welding”, explains Georg Knoll. Today, the experienced welding engineer oversees the welding processes at GROB and manages the workshop testing laboratory. “That’s why we have to constantly check from incoming goods to the finished assembled part: How is the bending behavior of the wire, does the geometry fit, does the insulation layer of paper sit between the hairpins and the sheet metal package, do the welds fit?” Because undetected defects can lead to loss of performance or inoperability, and in the worst case even to fatal damage to the entire drive.

Quality solutions for the complete manufacturing process

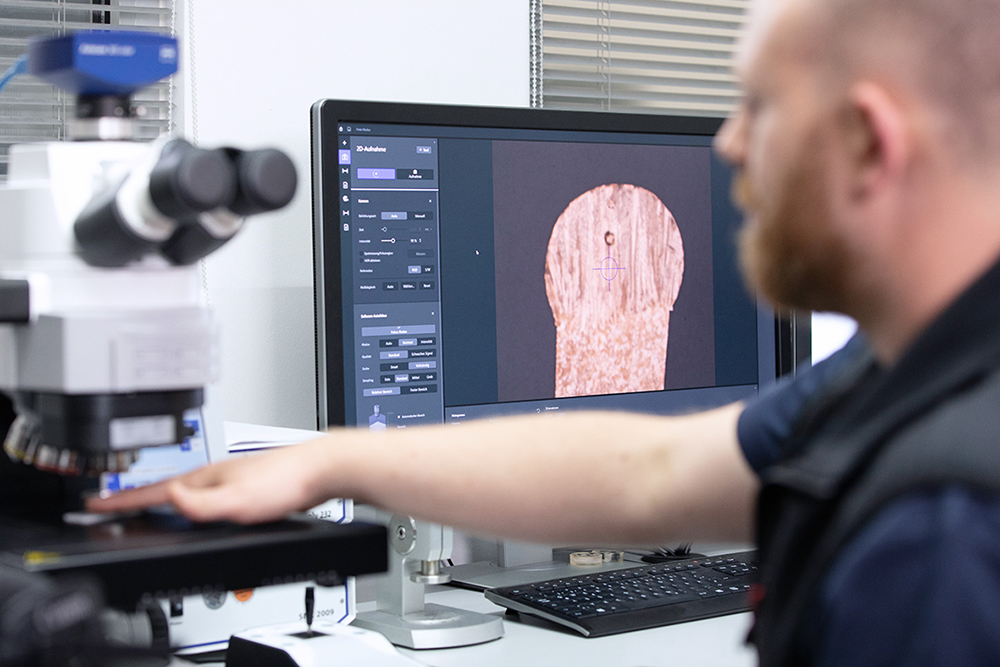

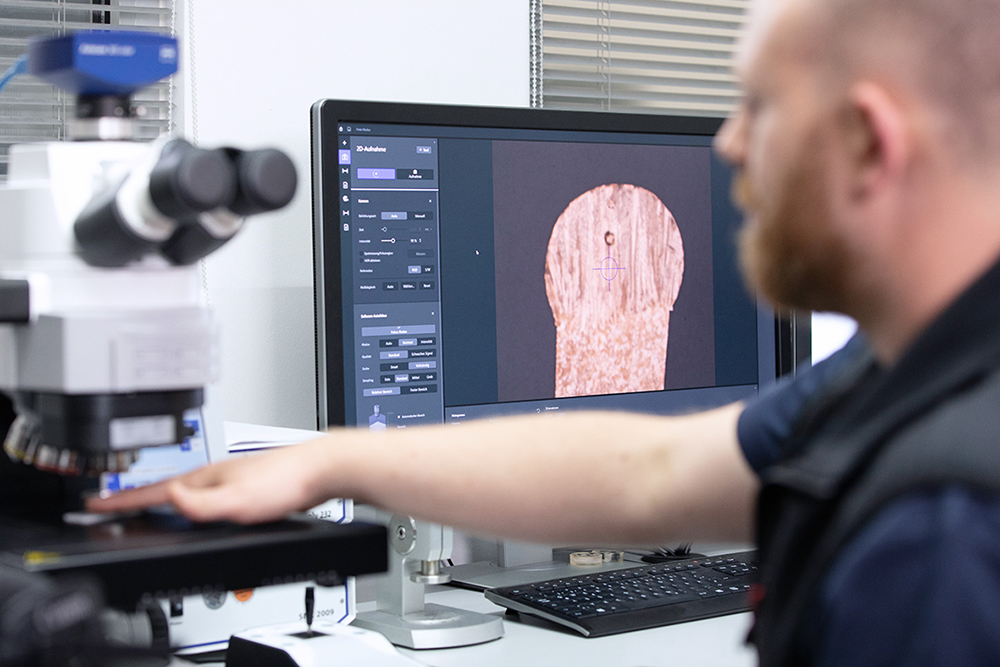

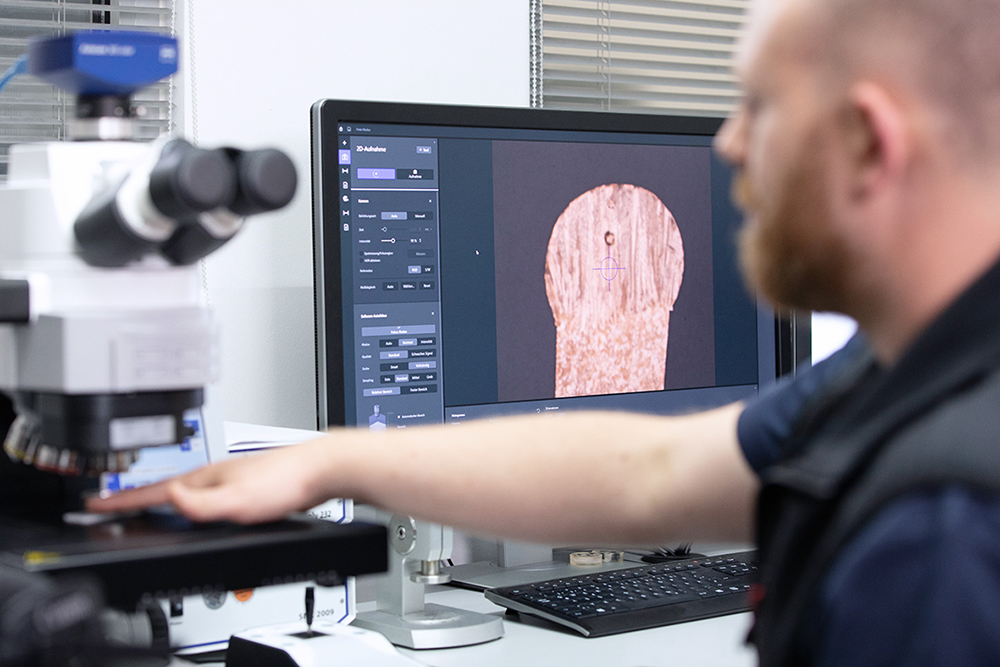

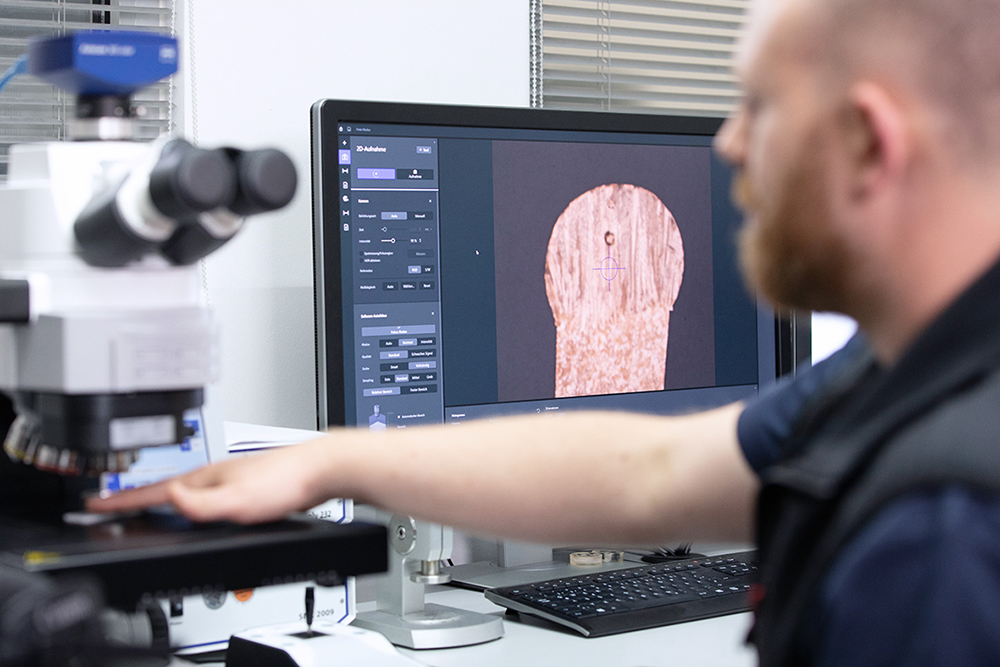

“Our claim is that we deliver a top manufacturing process to our customers, and our top priority is uncompromising quality,” says Martin Negele. “That’s why we also pay attention to quality assurance solutions in the production process, which meaningfully safeguard every single step. In this way, we always provide our customers with the certainty of consistently high quality.” A decisive focus is on the copper wire from which the hairpins are bent. On receipt of the goods, a tensile test is first carried out, then a cross-section of the wire is analyzed under the microscope with the aid of a metallographically ground sample. The visual inspection provides information about homogeneity and abnormalities on the surface, especially about the condition of the insulation coatings – aspects such as the thickness and size of the coating layer, dimensional accuracy, and deviations from the CAD model.

“It is essential for the manufacturing process that we see how the coiled wire behaves when we uncoil it for further processing, but also in terms of reverse bending behavior,” says Martin Negele. “Only with this knowledge can we guarantee consistently good results.” In the next step, the wire is bent into hairpins and the result is checked tactilely and optically on a multi-sensor coordinate measuring machine to ensure dimensional accuracy and homogeneity even when ready for assembly. Once the hairpins have been joined in the stack of sheets, further inspection steps follow: The welded ends of the hairpins are inspected with a computer tomograph. “As an experienced welding engineer, this is of course particularly important to me that we do a clean job here,” says Georg Knoll. “We have to be able to detect pores above a certain size or number so that we can adjust our processes accordingly.”

Standard from ZEISS used leads to 30 percent higher productivity

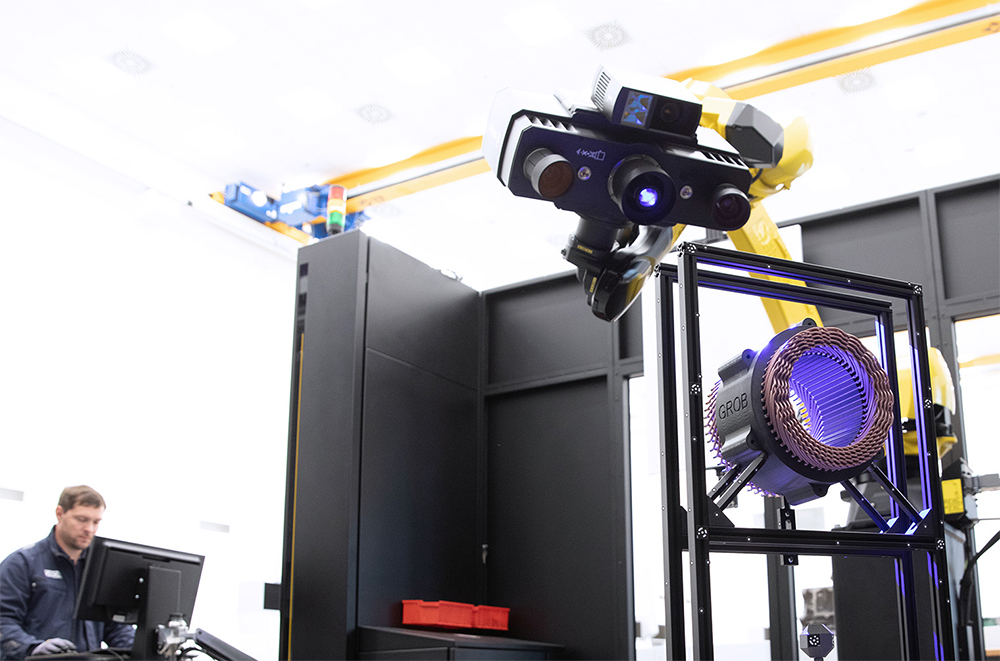

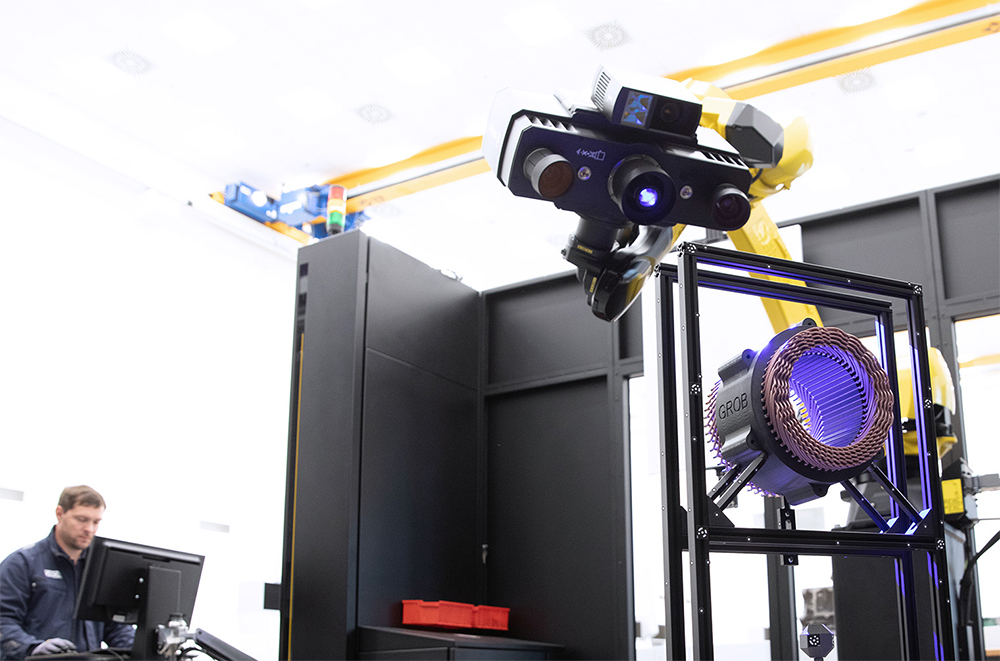

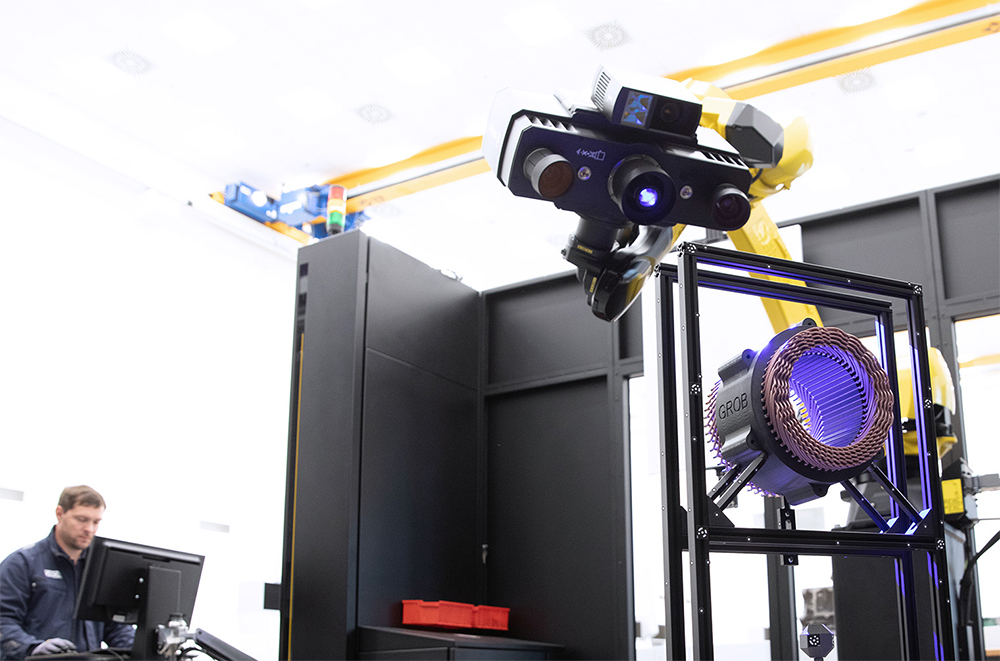

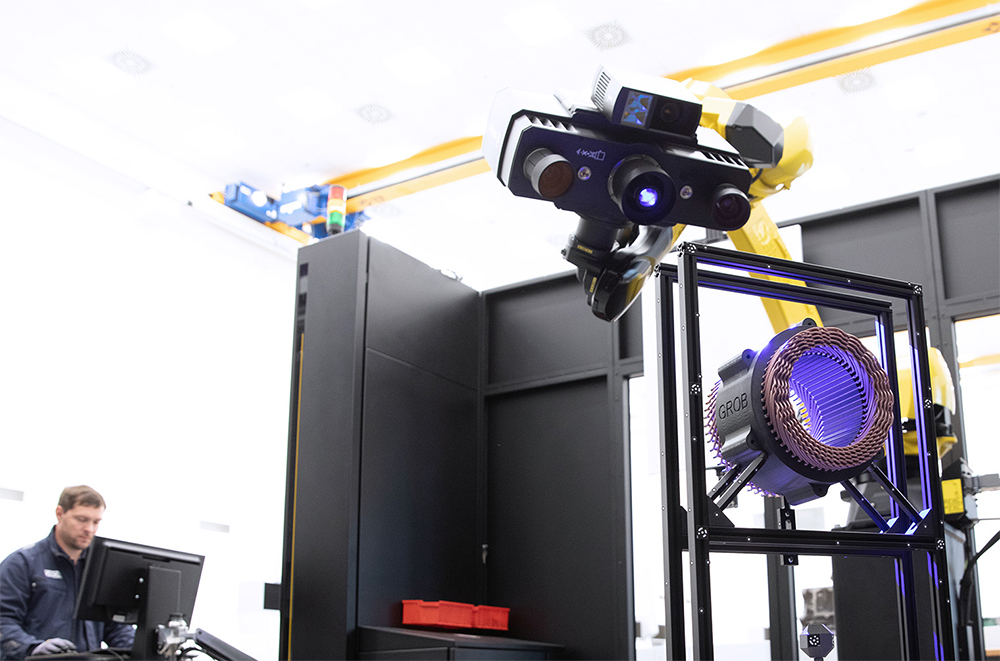

A glance into the measuring room – a hall of impressive size – reveals a clear brand preference in quality assurance technology: one ZEISS machine stands next to the other. As coordinate measuring machines, GROB relies on ZEISS PRISMO – one of the most precise of its kind. ZEISS ScanBox functions as an automated optical 3D measuring machine – it simultaneously enables high process reliability and a high throughput. And GROB also relies on proven ZEISS technology for microscopy with the ZEISS Axio Imager, an open microscope system for automated materials research. “With only few exceptions, we consistently rely on solutions from ZEISS,” explains Martin Negele.

“And there are several reasons for this: First, hardly any other supplier offers its industrial customers such a high level of service and application understanding. That simply convinces us time and again in the purchasing phase. And: No other supplier offers such a comprehensive portfolio with which we can cover an entire process such as the production of a stator.” The fact that almost all the devices in the measuring room come from ZEISS is not an end in itself, but has tangible advantages, emphasizes Martin Negele: “The uniform ecosystem saves us training effort and makes it easier for our employees to operate the different solutions. And it makes workload planning more flexible and efficient.”

As a result, our productivity has increased by 30 percent.

Georg Knoll adds: “And when our customers see our high-quality equipment from ZEISS, there are no discussions at all about quality claims or measurement values. They know that we employ state of the art solutions; after all, most of them have ZEISS equipment themselves.”

Technology leaders work together on the future of e-mobility technology

Thanks to the long-standing partnership, a relationship of trust has been established between GROB and ZEISS that goes beyond a mere supplier-customer relationship. GROB is also a pilot customer for new quality technologies from ZEISS before they are officially launched on the market, and supports their development with feedback. “This gives us access not only to the current state of the art in quality assurance solutions, but also helps shape them,” says Martin Negele.

“This fits in with our claim that we want to stay one step ahead of our customers, who are already operating at an extraordinarily high level, when it comes to quality. This is particularly important with new and emerging technologies such as e-motors or batteries – there is a lot to be gained for the pioneers, but only if they deliver quality. With ZEISS as our partner, we have the certainty of always being able to keep up with the leaders.”

ZEISS Industrial Quality Solutions

[email protected]

1-800-327-9735 zeiss.com/metrology